Robots have always been called "the jewel at the top of the manufacturing crown". Today, robots have been widely used in various industries and engaged in various jobs.

This is due to countless engineers and scientists tirelessly creating, improving, and in some cases redefining robotics. "Precision reducer" is one of the most critical and core parts of the robot.

Established in 2011, Leader Harmonious Drive Systems Co., Ltd has been focusing on the research and development of precision transmission devices such as harmonic reducers since its establishment. After years of hard work and independent research and development, Leaderdrive took the lead in mastering the core technology. The realization of the complete independent production of harmonic reducers is of great significance to promoting the independent development of the domestic robot industry. In August 2020, Leaderdrive was listed on the Science and Technology Innovation Board.

On October 16, Leader Harmonious Drive Systems Co., Ltd held the 2020 new product launch conference in Suzhou. The event was organized by the Lide Robotics Platform (Robot Lecture Hall), Professor Ding Han, Academician of the Chinese Academy of Sciences, China Robot Industry Song Xiaogang, executive director of the alliance, and more than ten top industry experts, Rong Deming, executive deputy mayor of Wuzhong District Committee of Suzhou City, Liu Yeming, party secretary of Mudu Town, Wuzhong District, Suzhou, and several government representatives, as well as nearly a hundred domestic and foreign Leaderdrive customers came to the scene and witnessed the fact that Leaderdrive has entered a new stage.

Zuo Jing, general manager of Leader Harmonious Drive Systems Co., Ltd, delivered a speech summarizing the past experience of Leaderdrive, and looking forward to the company's future path towards new development.

Rong Deming, member of the Standing Committee of Wuzhong District Committee and Executive Deputy District Mayor of Suzhou City, delivered a speech, expressing high praise and strong affirmation of the listing of Leaderdrive, and hoped that the location advantage of Suzhou could help enterprises develop faster and better in the future.

Break the monopoly, DNG flexible bearing new product release

At the site, Leaderdrive also released three new products at the same time, namely DNG non-fatigue flexible bearings, "Cyclone" series rotary actuators and M-work edge management system, showing strong continuous research and development capabilities.

Zhang Yuwen, deputy general manager of Leaderdrive, first introduced the first new product-DNG non-fatigue flexible bearings to the audience. Zhang Yuwen emphasized that DNG flexible bearings came from customer needs. Initially, in order to meet the high speed and high response requirements of SCARA robots, they obtained inspiration and innovation breakthrough points from SCARA robots with fast speed, short acceleration and deceleration time, and overload requirements. After a lot of tests, Leaderdrive found that under the same load conditions, the SCARA robot harmonic reducer flexible bearing inner ring receives more impacts than other operating conditions, and the impact load is greater. Inner ring fatigue is its service life shortboard.

Therefore, in view of the mechanism and characteristics of the fatigue failure of the flexible bearing inner ring, Leaderdrive adjusted the alloy element ratio of the bearing material through long-term exploration and research and adopted a new heat treatment and strengthening process to produce the latest fatigue-free DNG flexible bearings. The new DNG flexible bearings are more impact resistant and have a longer service life.

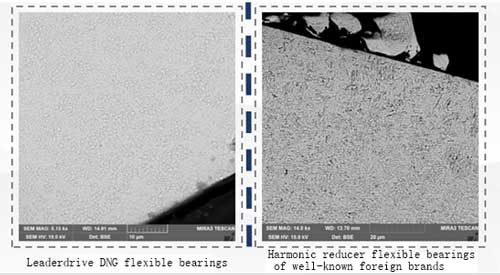

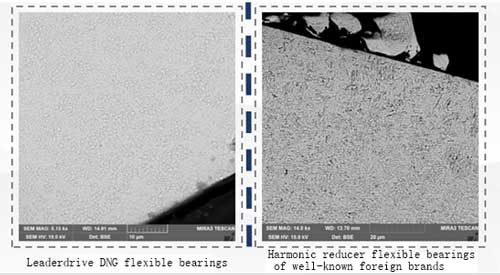

It is worth noting that in order to verify the reliability of the product, Leaderdrive has undergone a lot of tests and comparison experiments. By simulating the running state of the SCARA robot, under the same nearly 3 times load and motor acceleration test conditions of 6000r/min, the green LHSG series reducer using DNG flexible bearings were tested against foreign competitors for thousands of hours, and then the flexible bearings were tested. Analysis and comparison found that, regardless of surface fatigue, subsurface fatigue or near-surface fatigue, the Leaderdrive DNG flexible bearing is significantly better than the flexible bearing of the well-known foreign brand harmonic reducer.

The data and experimental results also prove that the latest DNG flexible bearing of Leaderdrive has undergone a large number of performance tests and bench tests to verify that there is no fatigue on the surface and subsurface of the inner ring raceway of the bearing after overspeed, overload, and long-term operation. Cracks, almost fatigue-free bearings. It shows the excellent impact resistance, fatigue-free and long-life performance of DNG flexible bearings.

Powerful Cyclone series rotary actuator

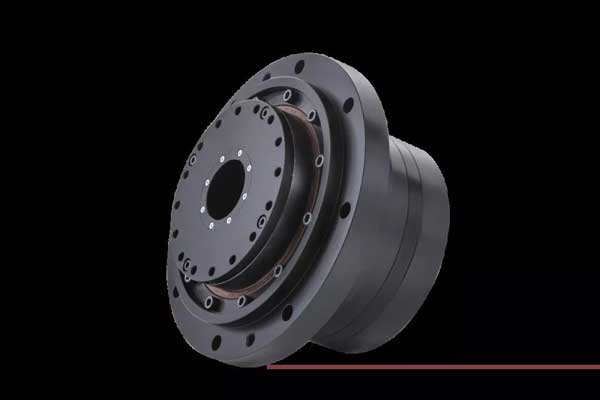

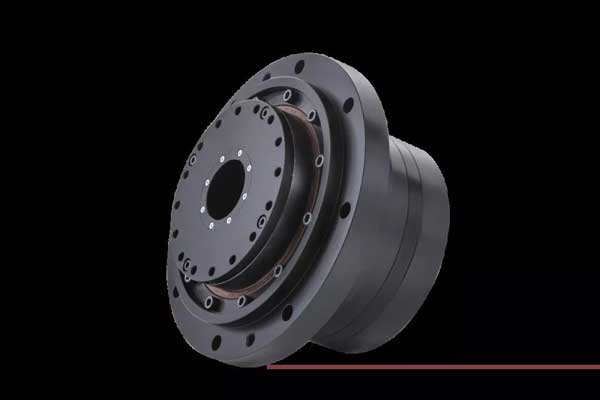

Subsequently, Dr Chu Jianhua, general manager of Jiangsu Kaixuan Intelligent, a subsidiary of Leaderdrive, also released the second innovation for intelligent equipment-Cyclone series rotary actuators.

Cyclone series rotary actuators are the result of dozens of R&D teams who have spent more than 3 years polishing and exploring new directions. It integrates special high-performance harmonic reducers, low cogging torque and high power density frameless torque motors. And special vibration and noise reduction design, successfully realized low vibration, low noise, low-temperature rise and smooth control, the absolute positioning accuracy is up to 10 arc seconds, the rigidity is 2~3 times higher than that of similar products, but it can be achieved in a small size output torque from 10N·m to 1470N·m.

Not only that, thanks to the optimized design of highly integrated mechatronic systems such as low-voltage and high-current bus-type servo drives, high-precision photoelectric encoders, ultra-thin electromagnetic brakes, and smart sensors, Cyclone series rotary actuators also have a fast response and many advantages such as longevity, zero backlashes, large aperture, high protection, maintenance-free, and extreme environmental temperature tolerance have been successfully applied in many fields such as semiconductors, medical equipment, laser processing, CNC machine tools, and factory automation.

M-work edge management system

At the end of the press conference, the latest strategic direction of Leaderdrive was also announced, the layout of the intelligent manufacturing direction, and a grand introduction to Suzhou Mahjong Intelligent Technology Co., Ltd. is a wholly-owned subsidiary of Leader Harmonious Drive Systems Co., Ltd. Always taking the mission of promoting intelligent manufacturing in discrete industries, focusing on data and intelligent technology innovation, and long-term commitment to provide comprehensive solutions such as robot application integration, smart factory planning and construction, and industrial information management systems for many enterprises facing transformation and upgrading The development and application of the scheme.

At the scene of Suzhou Mahjong Intelligent Technology Co., Ltd., the general manager Dr Hongfeng Zhao introduced Magic-work, a powerful edge management system, and proposed a set of software and hardware solutions for big data analysis and automation. Magic-work is oriented to the machining industry, large, medium and small enterprises, especially small and medium-sized enterprises, real-time monitoring of machine tools, manufacturing data management, collaborative operations, and many other CNC machinings such as low efficiency, error-prone, uncontrolled, and unscientific management. The problem is to focus on the data bridge between the equipment layer and the information layer in the construction of smart workshops.

It is worth mentioning that the Magic-work edge management system has MES, SCADA, WMS system functions, and can be closely integrated with the automated execution unit, which can provide enterprises with intelligent production lines, intelligent units, and workshop production management in the machining industry, quality management, visualized management of equipment management, intelligent tool system, online inspection, online tool repair, automated production line side warehouse material management and other services.

Expert's Message

After the release of the three new products, Professor Ding Han, Academician of the Chinese Academy of Sciences, Song Xiaogang, Executive Chairman of the China Robot Industry Alliance, Researcher Liu Jinchang from the Advanced Manufacturing Division of the High-Tech Research and Development Center of the Ministry of Science and Technology, and Professor Zhao Jie, Director of the Robotics Institute of Harbin Institute of Technology, four domestic top experts evaluated and summarized the new products.

Academician Ding Han expressed his affirmation that Leaderdrive insisted on independent research and development of core technologies and the parallel results of theory and practice in the past stage. At the same time, he also expressed his appreciation that Leaderdrive will penetrate into broader intelligent manufacturing in the future to provide core software and hardware solutions. The exploration is encouraged.

Song Xiaogang, Chairman of the China Robot Industry Alliance, in his concluding speech, expressed high praise for Leaderdrive’s adherence to theoretical innovation and achievement-oriented behavior in the current important stage of the reduction gear industry’s climbing research and encouraged the companies present to learn the Leaderdrive. Wave intervention in the key links of industrial basic parts and the determination and behavior of key materials to overcome difficulties will make greater contributions to the future robot and intelligent manufacturing industry in R&D, quality and reliability. At the same time, he also emphasized the importance of expanding from the field of single parts to the digital field of intelligent manufacturing. He believed that Siemens has become a provider of digital factory solutions from a PLC manufacturer with an extensive digital foundation and customer needs. It will be a viable road for the future development of leading manufacturers in the machinery industry.

From the perspective of national development, researcher Liu Jinchang recalled the development process of the core components of robots in the country from the 9th Five-Year Plan to the present 13th Five-Year Plan, using the expression "the hope of the national robot and the hope of the manufacturing industry" based on the past market sales and products of Leaderdrive. He highly praised the domestic core component companies represented by Leaderdrive and expressed his affirmation that the companies represented by Leaderdrive have begun to march toward intelligent manufacturing, CNC machine tools and many other aspects. He also expressed his appreciation for Leaderdrive. In the future, he put forward three pertinent suggestions of "taking a big step", "holding the pocket tightly", and "laying out the future", which received warm applause from the scene.

Professor Zhao Jie recalled the history of the project with Leaderdrive, affirmed the past of Leaderdrive adhere to the core technology, and expressed expectations for the future development of Leaderdrive in combination with the current 14th Five-Year Plan. Zhao Jie pointed out at the scene that the next fourteenth five-year plan will focus on supporting leading enterprises and backbone enterprises, and Leaderdrive will inevitably move from the domestic market to the international market in the future, which deserves the broader expectations of more industrial enterprises.

R&D Center Unveiling Ceremony & Expert Appointment Ceremony

Subsequently, Chairman Zuo Yuyu of Leader Harmonious Drive Systems Co., Ltd and Song Xiaogang, Chairman of China Robot Industry Alliance jointly unveiled the Leaderdrive R&D Center, which means a new journey for the research and development of Leaderdrive Core Components.

At the same time as the unveiling event, there was also an expert appointment ceremony. Chairman Zuo Yuyu and Liu Yeming, secretary of the Mudu Town Party Committee, Wuzhong District, Suzhou City, came to the stage together as Academician Ding Han, Chairman Song Xiaogang, Professor Zhao Jie, Professor Huang Qiang, and Professor Sun Lining After the domestic industry experts issued the appointment letter, the audience expressed their blessings to the appointment of experts with warm applause as the Leaderdrive.

Chairman Zuo Yuyu of Leader Harmonious Drive Systems Co., Ltd finally summarized the event and delivered a toast. At the same time, he also represented the concern and support of Leaderdrive to government leaders from all walks of life, and the guidance and assistance of industry experts and scholars. Partners from all walks of life and all employees expressed their heartfelt thanks.

Foundation laying of new plant

Immediately after the new product release was completed, in the morning of the 17th, Leaderdrive carried out the completion of the first phase of the new plant and the groundbreaking ceremony for the second phase of the project. Friends of Leaderdrive from the government, business and academic circles attended the event and congratulated Leaderdrive on its new journey of development.

At the event site, Zhang Yuwen, deputy general manager of Leaderdrive, first introduced the overall development of Leaderdrive Company and the company's future development plan under the new crown pneumonia epidemic in 2020.

He first reviewed the R&D of Leaderdrive 's new harmonic products and the listing of the company from the company's strategic level, and then explained in detail the importance of mass production of Y series reducers from the product level, and emphasized the integration of mechatronics products into the production system. And the future industrial chain upgrades strategy of the digital system, focusing on the strategic significance of the three new products for the company's production system and development route, and at the same time expressing the joy of opening a Leaderdrive new base after the new plant is laid.

Li Chaoyang, Deputy Secretary of Wuzhong District Committee and Acting District Mayor of Suzhou City, and Liu Yeming, Secretary of the Party Committee of Mudu Town, Wuzhong District, delivered guest speeches for the foundation laying of the new plant.

Liu Yeming, secretary of the Mudu Town Party Committee, explained the location advantages and industrial layout of Mudu Town, Wuzhong District, Suzhou from the government’s perspective. At the same time, he expressed his affirmation that high-end equipment manufacturing companies represented by green harmonics will land in Wuzhong District. Complimented Leaderdrive as the first listed sci-tech innovation board company in Wuzhong District for its courage to break the monopoly of foreign high-end harmonic reducers, and the ardent spirit of Leaderdrive to seize the development opportunities of the national manufacturing industry in the future I hope and urge the project construction party to speed up and complete the rapid and Leaderdrive development process of the second phase of the project. At the same time, he said that the district party committee and the government will also uphold the concept of responsiveness, and continue to support all types of enterprises in the town to seek various developments, serve the enterprises with all their heart, and strive to create a better investment environment for enterprise development, and help the Leaderdrive. The intelligent manufacturing enterprise represented by the company gradually establishes its core advantages and renews its glory.

Li Chaoyang, deputy secretary of the district party committee and acting district mayor, affirmed the past achievements of Leaderdrive and congratulated the completion of the first phase of the future Leaderdrive project and the foundation laying of the second phase of the new plant. He emphatically praised the Leaderdrive Sparrow platform. Believes that the Sparrow platform, as an important digital solution platform in Wuzhong District, will play an important role in improving the production capacity of the entire region, and will also make a significant contribution to the provision of better digital services in the national smart manufacturing market. Hope Leaderdrive will continue to carry forward innovation The entrepreneurial spirit of hard work, based on a new starting point and then climbing new heights, strives to build a leading domestic and world-class manufacturing enterprise.

Subsequently, more than a dozen political, business and academic figures from the Wuzhong District Government of Suzhou City, the China Robot Industry Alliance, and representatives of robotics industry enterprises, together with Leaderdrive Chairman Zuo Yuyu and Leaderdrive Zuo Jing, came to the stage at Lihua with the roar, the guests witnessed the exciting moment of the completion of the first phase of the Leaderdrive Phase 1 project and the foundation stone laying of the second phase of the new plant.

After the groundbreaking ceremony was completed, Leaderdrive also organized on-site personnel to visit Leaderdrive’s product exhibition hall and the first phase of the new factory. In the production workshop, people have seen that Leaderdrive has applied its own latest data management system to manage the process from product production, assembly to quality inspection in an all-round way. Several robots have also appeared on the production line of the new factory. Almost the entire process of unmanned production has been realized, which makes people feel that as a high-end equipment manufacturing parts enterprise, Leaderdrive’s high-end harmonic reducer products have not only made great contributions to the development of robots and other intelligent manufacturing industries. The advanced concept is actively adopting these intelligent manufacturing products to upgrade its own industrial development, and high-quality intelligent manufacturing products such as robots are providing new development momentum for Leaderdrive.

Conclusion

Leaderdrive is the first listed on the Science and Technology Innovation Board of China’s core components of robots. The three new products this time undoubtedly represent the great achievements of China’s core components breaking through the neck. Although domestic companies lead the domestic and foreign harmonic reducer market, lack of time, but I believe that under the leadership of a company that insists on developing and innovating core technologies like Leaderdrive, and has tackled key problems in a down-to-earth manner, the downstream companies will gradually increase their recognition and support for domestic products. Hand in hand, the future will inevitably be able to fully open the door of China's core parts companies to the world.

Publication Date: 20 October, 2020

Category:

Company News